Imagine a world where the tiniest components in your smartphone or a life-saving medical implant are assembled with a level of accuracy that the human eye can’t even detect. This isn’t science fiction—it’s the reality of modern manufacturing, driven by precision robotics that operate at scales as fine as a few micrometers. These machines, capable of repeatability within ±5 micrometers, are revolutionizing industries like electronics assembly and medical device production, where the smallest deviation can mean the difference between functionality and failure. As products shrink in size and grow in complexity, the demand for such pinpoint precision has become not just a competitive edge, but a fundamental necessity. This article explores how these robotic systems are reshaping two critical sectors, breaking through human limitations, and paving the way for innovations that touch every aspect of daily life. From microchips in wearables to intricate drug-delivery systems, the impact of this technology is profound, merging the boundaries between electronics and healthcare in unexpected ways. The journey of precision robotics is a story of overcoming challenges, finding smart solutions, and envisioning a future where even smaller, smarter devices become the norm.

Redefining Accuracy at the Micro Scale

Dive into the heart of precision robotics, and it’s clear that their ability to operate at micrometer and even sub-micrometer levels is nothing short of groundbreaking. For perspective, a single micrometer is one-thousandth of a millimeter—far finer than a strand of human hair, which measures around 70-100 micrometers thick. These robots achieve repeatability as tight as ±5 micrometers, meaning they can return to the exact same position over and over with astonishing consistency. Technical terms like accuracy, which measures closeness to a target position, and resolution, the smallest detectable movement, help define their capabilities. However, in industrial settings, repeatability often takes precedence, as systems can be fine-tuned through calibration to account for any offsets in controlled environments. This extraordinary precision is the backbone of modern manufacturing, enabling tasks that would be impossible by hand. It’s not just about being exact; it’s about doing so at a scale and speed that reshapes entire production lines, ensuring flawless outcomes for high-stakes products.

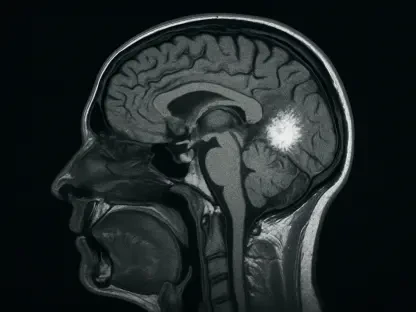

Beyond the numbers, the significance of this precision becomes evident in real-world applications. In electronics assembly, robots place semiconductor chiplets with tolerances of just ±1-3 micrometers, a feat critical for the performance of cutting-edge devices like smartphones and laptops. Similarly, tasks such as wire bonding at pitches of 25-50 micrometers or assembling optical modules for cameras demand this level of exactness to maintain quality at mass scale. Medical manufacturing mirrors this need, using robotics to bond microfluidic chips for diagnostics or to assemble intricate components in insulin pumps. Here, precision isn’t just about efficiency—it’s about ensuring patient safety and device reliability. The ability of robots to handle these microscopic tasks with unwavering steadiness highlights their transformative role, bridging the gap between what’s conceivable and what’s achievable in both sectors.

Breaking Through Human Barriers

Human hands, for all their skill, can’t keep up with the demands of modern manufacturing when tolerances dip into the microscopic range. Even the steadiest fingers tremble, eyes miss flaws too small to see, and fatigue erodes consistency over long hours. Precision robotics step into this void with a level of stability and endurance that’s simply unmatched. Take, for instance, the assembly of miniature connectors in wearable tech—aligning components within a few micrometers requires a steadiness no person can sustain. Robots execute this with ease, ensuring each piece fits perfectly every single time. This isn’t just an improvement; it’s a necessity as products grow smaller and more intricate, pushing beyond the physical limits of human capability.

Moreover, the impact extends to highly specialized tasks where precision is non-negotiable. In medical device production, assembling catheters involves threading micro-wires and applying adhesives at scales below 100 micrometers. Similarly, welding stents demands accuracy within 10-20 micrometers to guarantee structural integrity. Robotics deliver this reliability at a pace that outstrips manual labor, cutting down errors that could have severe consequences. By eliminating the variability inherent in human work, these systems ensure that every device, whether a tiny sensor or a life-saving implant, meets stringent standards. This shift isn’t about replacing people—it’s about empowering industries to achieve what was once thought impossible, setting a new benchmark for quality and consistency.

Navigating Complex Challenges and Smart Fixes

Implementing precision robotics at such fine scales comes with a host of challenges that can test even the most advanced systems. Environmental factors like temperature fluctuations, subtle vibrations, or even minor airflow disruptions can throw off performance when working below 10 micrometers. Cleanroom standards, crucial for avoiding contamination, add another layer of complexity, especially in medical contexts where ISO 5-7 compliance is often mandatory. Then there are regulatory hurdles—medical manufacturing must adhere to strict guidelines like FDA rules and ISO 13485 standards to ensure patient safety. Balancing speed with precision, sourcing specialized tooling, and finding skilled engineers to manage these setups further complicate the picture. These obstacles aren’t minor; they’re significant barriers that demand innovative thinking to overcome.

Fortunately, tailored solutions are rising to meet these demands, smoothing the path for broader adoption. SCARA robots, with their planar design offering a sweet spot of rigidity and speed, often emerge as the ideal choice for micrometer-scale tasks across both electronics and medical fields. For high-speed needs, Delta robots provide an edge, while Cartesian stages excel in ultra-fine alignment scenarios like microfluidics assembly. Collaborative robots, or cobots, equipped with force-torque sensors, also shine when handling delicate materials in medical applications. These varied architectures address specific pain points, from vibration control to material sensitivity, ensuring precision doesn’t come at the cost of practicality. As technology advances, ongoing refinements in environmental controls and automation software further mitigate disruptions, proving that while the challenges are steep, the industry’s knack for problem-solving keeps pushing boundaries.

Real-World Impact Across Industries

Precision robotics have cemented their place in electronics assembly, where they’ve long been indispensable for creating the devices that define modern life. Tasks like micro-soldering on flexible circuits, placing tiny connectors in smartwatches, and assembling optical modules for smartphone cameras all hinge on robots achieving tolerances tighter than a few micrometers. Without this capability, the sleek, powerful gadgets relied upon daily simply wouldn’t exist in their current form. The speed and consistency of robotic systems allow manufacturers to keep up with relentless demand while maintaining the quality that consumers expect. This isn’t a niche application—it’s the foundation of an entire industry, enabling everything from laptops to IoT devices to function flawlessly.

Meanwhile, medical device manufacturing is experiencing a parallel transformation as it adopts robotics to meet increasingly complex needs. Companies like Medtronic and Abbott are leveraging these systems to produce cutting-edge implants, drug-delivery mechanisms, and diagnostic tools with microelectronics embedded at their core. Assembling components for neurostimulation devices or bonding microfluidic channels for lab-on-a-chip systems requires the same micrometer-level accuracy seen in electronics. The stakes here are arguably even higher, as a single flaw could impact patient outcomes. Robotics ensure that every weld, every bond, and every inspection meets exacting standards, driving reliability in products that save lives. This growing reliance signals a broader trend: as medical devices integrate more electronic elements, the lines between these two sectors blur, unified by a shared dependence on robotic precision.

Looking Ahead to Limitless Possibilities

As remarkable as current achievements in precision robotics are, the horizon holds even more promise for both electronics and medical manufacturing. Innovations on the cusp of reality, such as AI-driven calibration to enhance sub-micrometer accuracy, are poised to redefine what’s possible. Smarter vision systems that counteract thermal drift and active vibration cancellation technologies could further stabilize operations at the smallest scales. These advancements aren’t just incremental—they’re set to unlock the assembly of next-generation devices, from bio-hybrid systems blending organic and synthetic components to optoelectronics pushing the limits of connectivity. The potential for smaller, smarter, and more integrated products seems almost boundless.

Reflecting on this trajectory, it’s evident that the strides made with precision robotics over recent years laid a robust foundation for what came next. Manufacturers overcame human limitations, tackled daunting environmental and regulatory challenges, and adapted to the converging needs of two vital industries. Suppliers like Yamaha Robotics and Fanuc played pivotal roles, delivering systems with ever-tighter repeatability to meet soaring demands. Looking forward, the focus must shift to scaling these innovations—investing in training for automation engineers, refining environmental controls, and fostering collaboration between tech developers and medical experts. Only by addressing these next steps can the full potential of sub-micron assembly be realized, ensuring that the tiniest components continue to power the biggest advancements in technology and healthcare.