In the high-stakes environment of cardiac care, where precision instruments can mean the difference between life and death, the reliability of medical technology is paramount. A significant safety concern has now emerged surrounding a critical device, as Johnson & Johnson’s subsidiary, Abiomed, initiated an urgent medical device correction for its Impella RP Flex heart pumps. This action followed the discovery of a malfunction risk that has already been connected to 22 serious injuries, prompting an early alert from the U.S. Food and Drug Administration (FDA). The agency is currently evaluating the issue as potentially high-risk, a classification reserved for problems that could cause serious harm or death. This development represents the latest in a series of safety-related actions involving the company’s widely used Impella heart pump systems, casting a spotlight on the oversight and performance of life-sustaining medical technology.

Unpacking the Technical Malfunction

The Nature of the Sensor Drift

The core of the problem lies within a critical component of the device: the differential pressure sensor. Over time, this sensor is susceptible to a phenomenon known as “drift,” where its calibrated values gradually shift, leading to the generation of erroneous and inaccurate information. This flawed data is then displayed on the automated Impella controllers, which are the primary interface for clinicians managing the device. The sensor drift directly compromises the readings for essential metrics, most notably the pump’s flow rate, which is a key indicator of how much support the heart is receiving. This misinformation can profoundly mislead the medical professionals who depend on this data to make split-second decisions about patient care. The FDA has emphasized a particularly concerning aspect of this malfunction: it is impossible for a user to directly confirm a flow calculation error from the pump’s signals alone when this drift occurs, making it a silent and insidious failure. This lack of a clear, immediate indicator of malfunction creates a hazardous situation where clinicians might unknowingly operate with incorrect information.

The consequences of this hidden data inaccuracy have been severe, directly contributing to the reported patient injuries. Relying on the erroneous flow rates displayed on the controllers, medical staff have been led to make improper adjustments to the heart pumps, either providing too little or too much support, which can destabilize a critically ill patient. In some of the 22 reported cases, the misleading data prompted clinicians to perform unnecessary device exchanges. This procedure, which involves removing the existing pump and inserting a new one, is an invasive and high-risk intervention, especially for patients already in a fragile state with right-sided heart failure. Each unnecessary exchange exposes the patient to potential complications such as bleeding, infection, vascular injury, or further cardiac distress. The injuries reported are a direct result of these clinical decisions made based on faulty information, highlighting the critical dependency on device accuracy and the devastating impact when that trust is broken by a technical flaw.

Corporate and Regulatory Response

In response to the identified risk, Johnson & Johnson has taken immediate steps to inform its customers about the potential for sensor drift. The company is actively distributing a formal notice to hospitals and healthcare providers who use the Impella RP Flex heart pump and is in the process of updating the device’s official instructions for use to include new warnings and operational guidance. A spokesperson for the company clarified a key point: while the sensor data may become unreliable, the drift does not impact the pump’s fundamental mechanical ability to provide hemodynamic support to the patient. Based on this, the company has advised that hospitals can continue to use the existing inventory of Impella RP devices, avoiding a full recall and removal from the market. This decision places the burden of risk mitigation squarely on the clinicians, who must now adapt their practices to work around the device’s known limitation. The communication strategy aims to prevent a disruption in the availability of this life-saving technology while simultaneously addressing the serious safety concerns that have emerged.

To help clinicians navigate this new reality, both Johnson & Johnson and the FDA have issued specific, harmonized guidance designed to mitigate the risks associated with the sensor malfunction. The primary directive for medical professionals is to fundamentally change how they interpret the device’s output. They are explicitly advised not to rely solely on the flow values displayed on the automated controller. Instead, they are instructed to incorporate a multi-faceted approach to patient monitoring, using other approved diagnostic tools, such as echocardiography or thermodilution catheters, to independently verify the patient’s hemodynamic status. Furthermore, before making any clinical interventions based on suspected changes in pump performance, staff should use imaging to verify the pump’s positioning within the heart. Finally, clinicians are directed to refer to the updated flow rate tables provided in the new instructions for use as a more reliable reference than the live controller display, fundamentally altering the standard workflow for managing patients on this device.

A Pattern of Safety Concerns

A History of Recalls and Alerts

This recent medical device correction is not an isolated incident but rather part of a broader, troubling pattern of safety concerns surrounding Abiomed’s heart pump systems. In December 2024, the company had already updated the instructions for the same two Impella RP devices involved in the current alert. That earlier action was precipitated by a risk that the pumps could temporarily or permanently stop functioning. The severity of that issue prompted the FDA to issue a Class I recall notice in January 2025. A Class I recall is the agency’s most serious designation, used in situations where there is a reasonable probability that the use of or exposure to a violative product will cause serious adverse health consequences or even death. This prior event established a significant precedent of critical failure modes associated with this specific model, raising questions about the device’s overall design and reliability well before the current sensor drift problem came to light. The recurrence of safety issues with the same device model within such a short timeframe suggests a potential for systemic vulnerabilities.

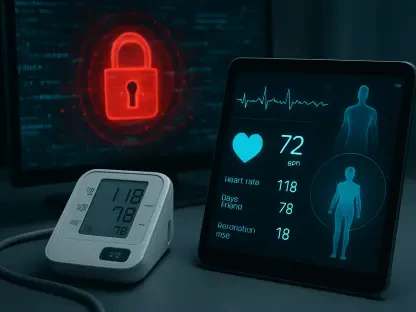

The safety concerns extend beyond the pump itself to encompass the entire Impella ecosystem. Throughout 2025, the automated Impella controllers, which serve as the “brain” for the various pump models, were the subject of several recall and early alert notices for a range of different issues. These problems were not minor; they included significant software glitches that could affect device performance and, notably, cybersecurity vulnerabilities that could potentially allow unauthorized access or manipulation of the device’s functions. This series of alerts demonstrates that the potential points of failure are not confined to a single component but are distributed across the hardware and software of the system. The cumulative effect of these repeated warnings creates a challenging environment for hospitals and clinical staff, who must constantly adapt their protocols, manage device updates, and weigh the therapeutic benefits against a growing list of documented risks. This history of recurring issues across the product line suggests a persistent challenge in ensuring the comprehensive safety and security of these complex medical devices.

Looking Ahead at Regulatory Scrutiny

The FDA’s recent early alert regarding the sensor drift problem served as a precursor to what may become another formal recall notice as the agency continues its investigation. This proactive communication from the FDA signaled the seriousness with which it viewed the potential for patient harm. The ongoing review process involved a thorough analysis of the 22 reported serious injuries and an assessment of Abiomed’s proposed corrective actions, including the updated instructions for clinicians. The agency’s final determination on whether to escalate the action to a formal recall, and at what classification level, depended on its evaluation of the effectiveness of these mitigation strategies. The scrutiny placed on Johnson & Johnson and its subsidiary highlighted the rigorous post-market surveillance that is essential for ensuring the long-term safety of complex medical devices after they have been approved for use in patients. The outcome of this investigation set a precedent for how manufacturers must address latent design flaws that emerge through real-world clinical application.