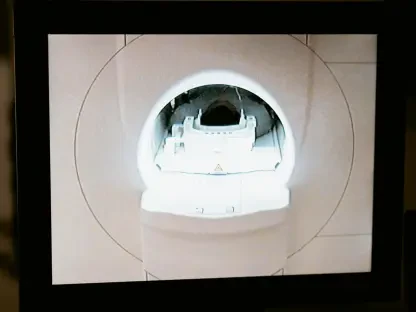

In a challenging turn of events for Integra Lifesciences, a significant recall of their cranial drills has brought intense scrutiny upon the company, emphasizing the inherent risks found in medical device manufacturing. These cranial drills, specifically the Codman cranial perforators, have been linked to a defect that compromises their safety during surgical procedures—a revelation that has surfaced in tandem with 10 reported injuries. The key issue with these devices lies in their structural integrity, as they have demonstrated a tendency to break apart unexpectedly. This potential for breaking poses severe risks, such as fragments becoming lodged within patients’ skulls or, more critically, causing brain injuries, which underscores the gravity of this defect. Such failures not only delay crucial medical procedures but also introduce additional complications, such as challenges in removing the broken parts and dealing with associated bleeding. Despite no fatalities reported to date, the FDA has taken these incidents seriously, marking several Class I recall entries—indicative of the most severe recall category.

Extensive Recall Efforts

Thousands of Devices Under Scrutiny

Integra Lifesciences’ recall involves a substantial number of devices, each variant harboring risks related to structural failure. Specifically, the company has instigated a recall encompassing over 170,510 units of its disposable cranial perforators alongside 1,840 craniotomy kits containing these flawed tools. Additionally, Medline Industries, a collaborator, has also been involved with recalls linked to similar devices. The root cause of this alarming defect has been traced to subpar welds within certain lots, ultimately affecting the device’s performance and reliability. This manufacturing oversight has resulted in devices that are highly susceptible to malfunction during critical surgical operations. The vast number of units impacted highlights the extensive reach and consequential nature of this issue across healthcare facilities where these tools are employed. These large-scale recall efforts underscore the urgency and attention necessary to mitigate potential patient harm while assuring healthcare providers of the safety of surgical environments.

Addressing Regulatory Compliance

Underlying these recalls is a history of regulatory scrutiny that Integra Lifesciences has faced over the past year. Previously, the FDA issued Form 483s which pointed out noncompliance issues, particularly concerning quality system regulations that include cranial perforators. These critical feedback points escalated into a formal FDA warning letter in the previous year, urging the company to enhance its regulatory compliance measures. In response, Integra developed a comprehensive compliance plan, aiming to tackle the noted deficiencies and demonstrating a proactive commitment to remedy these lapses. The company estimated significant financial impacts resulting from halted shipments, reportedly amounting to approximately $27 million. This figure not only reflects the immediate financial strain but also captures the broader implications on the company’s operational trajectory and future reputation in the medical device market. Integra’s concerted efforts indicate an acknowledgment of regulatory demands while highlighting the strenuous nature of conforming to evolving safety standards.

Financial Implications and Strategic Adjustments

Economic Impact of Compliance Initiatives

The financial implications of the recall and associated compliance initiatives have exerted considerable pressure on Integra Lifesciences. CEO Mojdeh Poul, during regular stakeholder updates, acknowledged the potential elevation of full-year estimates for shipment holds, projecting figures between $55 million and $70 million. These projections illustrate the broader economic repercussions that companies face when aligning with regulatory expectations while maintaining production momentum. The necessity to halt shipments temporarily for quality reassessment has introduced complexities in delivering timely medical solutions, underscoring the balance companies must strike between safety and operational expediency. Additionally, this financial burden extends to anticipating long-term strategic adjustments, necessary for regaining market trust and ensuring sustained growth.

Navigating the Path Forward

Despite the setbacks, Integra expressed optimism about completing all corrective actions mandated by the FDA within the current year. Such affirmative assessments suggest that the company is on track with implementing the required changes, endeavoring to prevent similar incidents in the future. The consequences of maintaining noncompliance not only influence immediate fiscal outcomes but also reshape the company’s strategic direction. Moving forward, compliance with rigorous safety and quality standards becomes pivotal, dictating product development, manufacturing processes, and broader market positioning. By addressing core issues and reinforcing commitment to safety, Integra aims to restore its reputation, ensuring healthcare practitioners and patients alike that its medical devices are trustworthy and reliable.

Industry Challenges and Future Considerations

Balancing Production with Regulatory Demands

This recall event reflects broader challenges within the medical device manufacturing sector, where balancing production imperatives and regulatory adherence remains a persistent struggle. Manufacturers face constant pressure to deliver advanced tools that meet evolving healthcare needs, all while complying with stringent safety regulations enforced by worldwide health authorities. When discrepancies arise, as seen with Integra, they prompt significant operational adjustments, necessitating both technological innovation and a robust quality assurance strategy. These high-pressure conditions illustrate the complexities that companies must navigate to avoid the pitfalls of noncompliance and adverse incident reporting.

Strengthening Industry-Wide Practices

Integra Lifesciences faces considerable scrutiny following a substantial recall of their Codman cranial perforators. These medical devices, crucial in surgical procedures, are plagued by structural flaws that raise significant safety concerns. The defect has been linked to 10 injuries, as the drills demonstrate a propensity to unexpectedly break apart, posing severe risks of fragments embedding in patients’ skulls or causing brain injuries. These complications not only delay essential medical operations but also introduce hurdles in extracting broken parts and managing resultant bleeding. Although no fatalities have been reported, the gravity of the situation is underscored by the FDA’s classification of several incidents as Class I recalls, the most serious in their category. This reflection of the inherent risks in medical device manufacturing highlights the urgent need for stringent quality control to prevent such defects, ensuring patient safety and maintaining trust in healthcare products.