Imagine a world where surgeries are performed with pinpoint accuracy, reducing recovery times dramatically, and factory floors hum with machines that work tirelessly alongside humans to produce flawless products at record speeds. This is not a distant vision but the reality unfolding today, as robotics emerges as a transformative force in healthcare and manufacturing. These industries, critical to global well-being and economic stability, are witnessing a seismic shift driven by advanced robotic systems. Efficiency is soaring, costs are plummeting, and quality is reaching new heights, all thanks to technology that once seemed like science fiction. From hospitals to production plants, robots are solving long-standing challenges, proving their worth as indispensable allies in progress. The economic implications are staggering, with market projections pointing to billions in growth over the coming years. More than just numbers, this revolution is opening doors to innovation, scalability, and a future where human potential is amplified by machine precision. As this wave of change accelerates, understanding its depth and breadth becomes essential for staying ahead in an increasingly automated world.

Healthcare: A New Era of Precision and Care

Surgical Precision and Patient Outcomes

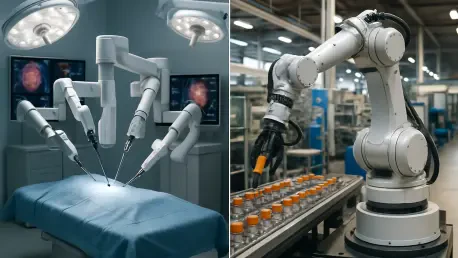

Robotic systems are redefining the landscape of healthcare by bringing unparalleled precision to surgical procedures. Advanced platforms like the da Vinci system allow surgeons to perform complex operations through tiny incisions, minimizing trauma to patients. This results in fewer complications, shorter hospital stays, and faster recovery periods, which not only improve patient outcomes but also enhance the reputation of medical facilities adopting such technologies. Hospitals equipped with these tools can handle a higher volume of cases without sacrificing quality, addressing the growing demand for specialized care. The ripple effect is significant—patients return to their lives sooner, while healthcare providers see a reduction in post-operative costs and resource strain. This precision-driven approach marks a turning point, setting a new standard for what’s possible in modern medicine.

Beyond the immediate benefits to patients, the adoption of surgical robotics is reshaping how healthcare systems operate on a broader scale. The ability to perform minimally invasive procedures means that even high-risk patients, who might have been deemed unsuitable for traditional surgery, can now receive treatment with lower risk. Data indicates that millions of robotic-assisted surgeries are performed annually worldwide, reflecting a growing trust in these systems among medical professionals. This trend also drives competition among hospitals to invest in cutting-edge technology, ultimately benefiting patients through access to better care. As robotics continues to evolve, its integration into surgical practices promises to tackle even more complex medical challenges, ensuring that precision remains at the forefront of patient care strategies.

Automating Routine Tasks and Beyond

In addition to transforming surgeries, robotics is streamlining routine tasks within healthcare settings, freeing up valuable time for medical staff. Robots now handle repetitive duties such as medication delivery, diagnostic imaging, and facility disinfection with remarkable efficiency. This automation reduces human error, ensures consistency, and allows nurses and doctors to focus on direct patient interaction and critical decision-making. The impact is especially evident in high-pressure environments like emergency rooms, where every second counts, and staff burnout is a constant concern. By taking on these labor-intensive tasks, robots help improve patient turnover rates and cut operational expenses, creating a more sustainable model for healthcare delivery. This shift is proving vital as facilities grapple with staffing shortages and rising patient numbers.

Looking beyond the basics, robotics is venturing into innovative applications that address emerging healthcare needs. Wearable exoskeletons, for instance, are aiding rehabilitation by supporting patients in regaining mobility after injuries or strokes. Telepresence robots enable remote consultations, connecting specialists with patients in underserved areas, while companion robots offer emotional support to the elderly, combating loneliness in aging populations. These advancements are not just conveniences but necessities in a world facing demographic shifts and increasing demand for personalized care. The ability of robots to adapt to such diverse roles highlights their potential to fill gaps in human resources, ensuring that healthcare systems remain responsive and resilient in the face of growing challenges.

Manufacturing: Boosting Production and Quality

Collaborative Robots and Production Efficiency

Manufacturing is undergoing a profound transformation with the integration of collaborative robots, often referred to as cobots, which are designed to work safely alongside human operators. Unlike traditional industrial robots confined to isolated tasks, cobots adapt to a variety of functions without the need for extensive reprogramming, making them incredibly versatile. This flexibility accelerates production processes, allowing companies to scale output rapidly to meet fluctuating market demands. In industries like electronics and automotive, where precision and speed are paramount, cobots are proving to be game-changers by enhancing workflow efficiency. The result is a significant boost in productivity without a proportional increase in labor costs, positioning manufacturers to stay competitive in a global economy.

The economic advantages of adopting cobots extend beyond mere output gains, as they also address critical pain points like workplace safety and resource optimization. By handling repetitive or physically demanding tasks, these robots reduce the risk of injury to human workers, fostering a safer working environment. Material-handling robots, a subset of this technology, further minimize waste in high-cost sectors by ensuring precise movement of components, cutting down on errors that lead to defective products. This efficiency translates into faster order fulfillment and the ability to take on larger contracts without expanding the workforce. As manufacturers embrace this technology, the shift toward automation becomes a strategic necessity, ensuring they can keep pace with industry standards and customer expectations.

Quality Control with Vision-Guided Systems

Quality control in manufacturing has reached new heights with the deployment of vision-guided robotic systems that detect defects early in the production cycle. Equipped with advanced imaging and sensor technology, these robots scrutinize products with a level of detail unattainable by the human eye, identifying flaws before they escalate into costly issues. This early intervention protects brand reputation by ensuring only high-quality goods reach the market, a critical factor in industries where consumer trust is paramount. The consistency offered by these systems also reduces the likelihood of recalls, saving companies from financial losses and legal repercussions. As a testament to their impact, the rapid global adoption of such technology underscores its role as a cornerstone of modern manufacturing excellence.

The broader implications of vision-guided robots lie in their ability to integrate seamlessly into existing production lines, enhancing rather than overhauling current processes. Their real-time analysis capabilities provide manufacturers with actionable insights, allowing for immediate adjustments to prevent recurring defects. This not only minimizes material waste but also optimizes resource allocation, aligning with sustainability goals that are increasingly important to stakeholders. With over half a million industrial robots installed in a single recent year, the momentum toward automation is undeniable. This widespread shift signals that robotics is no longer an optional investment but a fundamental component of maintaining a competitive edge, ensuring that quality remains a defining feature of manufactured goods.

Technological Advancements Fueling Robotics

AI and Machine Learning Integration

The fusion of artificial intelligence (AI) and machine learning with robotics is propelling these systems into a realm of unprecedented capability. No longer limited to pre-programmed tasks, robots can now learn from their surroundings, adapt to changing conditions, and execute complex functions with a level of dexterity akin to human skill. In healthcare, this means safer and more accurate surgical procedures, as robots adjust in real-time to subtle variations during operations. In manufacturing, AI-driven robots optimize assembly lines by predicting bottlenecks and suggesting workflow improvements. This intelligent automation is reshaping operational dynamics, making systems not just reactive but proactive in enhancing efficiency across diverse applications.

Moreover, the continuous learning aspect of AI integration ensures that robotic systems grow more effective over time, refining their performance with each task. This adaptability is particularly crucial in environments where precision and safety are non-negotiable, such as operating rooms or high-speed production facilities. The ability to process vast amounts of data also allows robots to contribute to strategic decision-making, identifying inefficiencies that might escape human oversight. As these technologies mature, their impact extends beyond immediate task execution to long-term process optimization, setting a new benchmark for what automation can achieve. The synergy of AI with robotics is thus a driving force behind smarter, more responsive industrial and medical ecosystems.

Real-Time Feedback and Dexterous Capabilities

Real-time feedback systems are enhancing the functionality of robots by enabling immediate responses to environmental changes, a critical feature for collaborative settings. Coupled with tactile sensing, these systems allow robots to handle delicate tasks with precision, whether it’s manipulating surgical instruments or assembling intricate components in manufacturing. This dexterity ensures that robots can perform roles requiring fine motor skills, reducing the margin for error in high-stakes scenarios. The safety benefits are evident as well—robots equipped with such feedback mechanisms can detect human presence or unexpected obstacles, adjusting their actions to prevent accidents. This capability is redefining how robots interact with their surroundings, making them reliable partners in complex operations.

The ongoing development of dexterous robots is also paving the way for broader applications that demand nuanced interaction. In healthcare, these robots assist in procedures where even slight missteps can have significant consequences, ensuring consistent outcomes. In industrial contexts, their ability to manage fragile or irregularly shaped materials without damage boosts production quality. Continuous improvement through feedback loops means that each interaction refines their performance, creating a cycle of increasing efficiency. As tactile and sensory technologies advance, the scope of tasks robots can undertake expands, bridging the gap between mechanical automation and human-like finesse. This evolution underscores the transformative potential of robotics in achieving operational excellence across sectors.

Strategic Adoption for Lasting Impact

Small-Scale Pilots and Measurable Results

Implementing robotics effectively begins with a cautious, step-by-step approach, often through small-scale pilot projects that target specific operational challenges. These initial deployments allow organizations to test the technology in controlled settings, measuring outcomes like cost savings, time efficiency, and quality improvements before committing to wider adoption. In healthcare, a pilot might involve using a robotic system for a limited set of surgeries to assess patient outcomes and staff adaptation. In manufacturing, it could mean introducing a single cobot to a production line to gauge its impact on output. This method minimizes risk, builds confidence among stakeholders, and provides concrete data to justify further investment, ensuring that the transition to automation is grounded in real-world results.

The value of starting small lies in its ability to reveal practical insights that larger rollouts might overlook. Pilot projects often uncover unforeseen hurdles, such as integration issues with existing systems or the need for tailored staff training, allowing for adjustments early on. Success in these limited trials can also serve as a powerful motivator, demonstrating tangible benefits to skeptical teams or budget-conscious executives. By focusing on measurable metrics—such as reduced recovery times in hospitals or decreased defect rates in factories—organizations can build a compelling case for scaling up. This deliberate approach ensures that robotics adoption aligns with specific goals, maximizing impact while mitigating the financial and operational risks associated with untested technology.

Training and Transparency with Staff

A critical component of successful robotics integration is prioritizing training and transparency to address workforce concerns. Employees in both healthcare and manufacturing often harbor apprehensions about automation leading to job displacement, making it essential to educate them on how robots enhance rather than replace their roles. Comprehensive training programs should focus on teaching staff to operate, monitor, and collaborate with robotic systems, ensuring they feel empowered rather than threatened. In hospitals, this might involve surgeons learning to use robotic surgical tools, while in factories, workers could be trained to program cobots for specific tasks. Such initiatives foster a sense of ownership and demonstrate the technology’s value as a supportive tool, easing the cultural shift toward automation.

Transparency plays an equally vital role in building trust during this transition, as clear communication about the purpose and benefits of robotics can dispel myths and resistance. Leadership must articulate how these systems aim to alleviate repetitive or dangerous tasks, allowing workers to focus on higher-value responsibilities like patient care or creative problem-solving. Regular updates on pilot results, future plans, and opportunities for input can further reinforce a collaborative atmosphere. By addressing fears head-on and showcasing real examples—such as nurses having more time for patient interaction or factory workers avoiding injury—organizations can align their teams with the broader vision. This human-centered approach ensures that robotics becomes a unifying force rather than a divisive one in the workplace.

Building ROI Models for Long-Term Success

Developing a robust return-on-investment (ROI) model is fundamental to justifying the adoption of robotics and ensuring its sustainability. Such models must account for both immediate costs—like purchasing and installation—and long-term gains, including reduced operational expenses and increased revenue potential. In healthcare, this could mean calculating savings from shorter patient hospital stays against the upfront cost of surgical robots. In manufacturing, it might involve weighing the expense of cobots against gains in production speed and quality. A well-structured ROI framework provides a clear picture of financial impact, helping decision-makers prioritize investments and allocate resources effectively. This data-driven strategy is essential for aligning robotics initiatives with organizational goals.

Beyond financial metrics, ROI models should also consider qualitative benefits that contribute to long-term success, such as improved patient outcomes or enhanced product reliability. Tracking these intangibles alongside hard numbers offers a holistic view of robotics’ value, supporting continuous refinement of implementation strategies. For instance, a hospital might note higher patient satisfaction scores as a secondary benefit of faster recoveries, while a manufacturer could highlight improved brand loyalty due to consistent quality. Regularly updating these models to reflect real-world performance ensures adaptability as technology and market conditions evolve. By balancing cost with comprehensive impact, organizations can secure stakeholder buy-in and position robotics as a cornerstone of future growth in both sectors.

Shaping Tomorrow’s Industries

Reflecting on the strides made in robotics, it’s evident that the journey over recent years has delivered remarkable progress in healthcare and manufacturing. Surgical precision has improved patient lives, while factory automation has elevated product standards, with both sectors reaping substantial economic rewards. Challenges like high costs and regulatory barriers have been met with innovative solutions and persistent effort, paving the way for broader adoption. The collaboration between human ingenuity and machine efficiency has proven to be a winning formula, setting benchmarks that have reshaped industry expectations. Looking back, the strategic focus on training, pilot projects, and measurable outcomes has laid a solid foundation for sustained impact.

Moving forward, the path involves harnessing analytics and evolving technologies to push boundaries even further. Industries should prioritize scalable frameworks that integrate robotics with data-driven insights, ensuring continuous improvement. Investing in cross-sector partnerships could accelerate innovation, blending healthcare’s precision needs with manufacturing’s efficiency models. Policymakers might consider streamlined regulations to ease adoption, while organizations should commit to upskilling workforces for emerging roles. The next steps lie in embracing adaptability, viewing robotics not as a static tool but as a dynamic asset poised to redefine operational excellence. This forward-thinking mindset will ensure that the benefits of automation continue to unfold, driving progress for years to come.