Amid mounting imaging volumes and staffing constraints that challenge even the most seasoned departments, the latest wave of AI‑powered modalities promised a path to faster, more consistent exams without trading away diagnostic confidence or dose stewardship. The showcase positioned automation not as a novelty layered onto legacy workflows, but as a design principle embedded from acquisition to review, folding guidance, reconstruction, and positioning into the technologist’s natural flow. That ambition mattered because small inefficiencies scale into missed time slots and repeat imaging, while subtle variations in technique can ripple into uneven outcomes. By linking MRI, digital radiography, mobile radiography, and mobile fluoroscopy under a single, workflow-first vision, the portfolio aimed to close that gap between peak image quality and everyday operational reality.

Imaging performance meets operational efficiency

AI-driven MRI enhancements

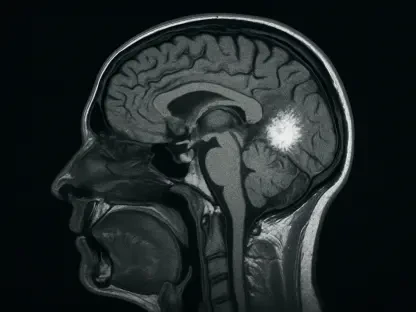

In MRI, the headline was not a new magnet but a rethinking of image creation and planning through software intelligence, starting with DLR Symmetry. This deep learning reconstruction applied a trained model to undersampled data, using partial Fourier strategies to recover detail typically sacrificed in accelerated scans. The intent was straightforward: maintain sharpness and contrast while shaving minutes from acquisition, a combination that can improve patient comfort and reduce motion artifacts. Beyond speed, the method addressed a thorny issue—how to accelerate without seeding ringing or blur—by tuning the reconstruction to anatomical structures rather than relying solely on generic filters. In practice, this could stabilize results across body habitus and vendors, helping radiologists trust that fast does not mean fragile.

Paired with that, AutoPose with AI pushed automation upstream to the moment that defines exam quality: slice planning. Extending automated planning to the chest, cardiac, pelvis, and lower extremities confronted variable anatomy and motion head-on, where manual planning traditionally lengthens setup and breeds inconsistency. The system analyzed scout images to set planes and coverage, reducing operator variability and helping a busy technologist deliver the same alignment a seasoned specialist would. That standardization did more than save keystrokes; it created comparable studies for longitudinal follow-up and multi-site trials. It also unlocked more predictable scanner throughput, since fewer ad‑hoc adjustments meant a tighter schedule and fewer rescans for missed anatomy or oblique angulation.

Portable DR at the point of care

At the bedside, the FDR Go iQ treated portability as an enabler rather than a compromise, threading premium image quality through a mobile form factor tuned for inpatient and emergency care. A tube head touch display put crucial controls at arm’s reach, trimming the back‑and‑forth that slows bedside exams. In‑bin detector smart charging targeted a persistent pain point—battery management—by reducing swaps and ensuring detectors remain ready across a shift. The star, however, was the integrated 3D camera that observed positioning in real time, providing tube‑to‑bed angulation feedback and automatic SID sensing so the first exposure had the best chance to be the only exposure. In crowded ICUs, that guidance could translate into fewer retakes and less patient disturbance.

Equally important, the system’s guidance cues mirrored how technologists think under pressure, avoiding cryptic prompts in favor of immediate, visual coaching. That design choice acknowledged the cognitive load at the bedside, where lines, drains, and limited access make textbook geometry unrealistic. By nudging users toward optimal alignment and alerting when projection or distance deviated, the device reduced the guesswork that often leads to grid cutoff, clipped anatomy, or uneven penetration. The practical outcome was not just nicer images—it was predictability. Consistent technique made dose mapping meaningful and enabled protocols that stood up across shifts and skill levels. In aggregate, those small wins preserved minutes per exam, adding capacity without new staff.

Automated radiography suites

For fixed-room radiography, the FDR Visionary suite approached standardization through choreography: auto‑positioning hardware, a collimator‑integrated camera for live visual guidance, and applications that extend the room’s repertoire. Automation brought the tube and detector into position with a tap, letting technologists focus on the patient rather than swim in menus. The camera—nested inside the hardware that defines the beam—provided a direct sightline for alignment, synchronizing what users saw with where the radiation would land. In practice, that alignment reduced the micro‑adjustments that steal seconds and introduced a discipline that made “first-time-right” a habit rather than a hope. For departments grappling with backlogs, shaving those seconds across a day created meaningful headroom.

The suite also broadened case coverage without diluting speed. Long‑length imaging at both the chest stand and table addressed spine and leg length studies with workflow that respected throughput, while optional bone subtraction and tomosynthesis opened pathways for subtle findings and pseudo‑3D lesion localization. These advanced applications sat inside a room that still behaved like a general X‑ray system, avoiding the toggle between specialty and routine that often complicates scheduling. Together, the components aligned with a simple thesis: precision should not slow a department down. By merging automation with advanced imaging, the room aimed to deliver consistent output across technologists while keeping dose predictable and operator burden low, a combination that resonates when volumes spike.

Or-ready fluoroscopy and workflow integration

Persona C-HR mobile C-arm

In the operating room, the Persona C‑HR set out to reconcile surgical demands with radiation vigilance, pairing a 25 kW generator and high‑sensitivity detection with 30 fps pulsed fluoroscopy. That power reserved headroom for larger patients and complex views, while pulsing limited exposure without starving the image of temporal resolution. An 82 cm opening expanded access around the table and implants, reducing the awkward contortions that can prolong cases. The hardware foundation would matter little without stamina, so active cooling supported longer procedures without throttling. Surgeon and technologist displays—anchored by a 32‑inch 4K monitor and a secondary control surface—distributed control and visibility, cutting the lag between image acquisition and decisions that guide delicate maneuvers.

Ergonomics played a quiet but decisive role. By giving surgeons a console that mirrored their intraoperative needs and technologists a dedicated interface for acquisition, the C‑arm reduced verbal back‑and‑forth and kept each role in its lane. That separation shrank cognitive overhead at moments when attention is scarce. High‑resolution imaging at low dose had downstream benefits too, exposing hardware outlines, stents, or guidewires with clarity that can shorten trial‑and‑error and curb cumulative exposure over a case. The lightweight chassis translated into finer positioning and less drift, and in cramped ORs that mobility reduced setup friction. In sum, the system framed image quality and workflow not as tradeoffs but as co‑requirements of modern minimally invasive and vascular surgery.

Cross-setting integration and dose management

Across modalities, the throughline was intelligence at the point of acquisition, not bolted‑on analytics after the fact. Interfaces that embedded guidance, positioning, and reconstruction within the same step aligned with how imaging staff work when speed and safety collide. That approach mattered for standardization: when devices coach technique and automate alignment, protocol adherence ceases to be a training artifact and becomes the default behavior. Dose management rode alongside, expressed in features such as pulsed fluoroscopy, high‑sensitivity detectors, and live SID sensing that keeps geometry honest. Rather than pitching dose as a separate initiative, the portfolio built it into the same mechanisms that lift efficiency and quality.

This convergence tracked with broader consensus: AI and automation now live inside the workflow loop, not in separate dashboards. It also anticipated a cross‑setting reality, where hospitals cannot afford fragmented performance between a flagship MRI suite and a rolling X‑ray cart. Consistent user experiences and guidance logic eased transitions for rotating staff, encouraging technique carryover from room to bedside. The strategy acknowledged that raw specifications rarely decide outcomes; reduced clicks, fewer retakes, and calmer setups do. By unifying these priorities, the systems positioned departments to pursue ALARA without slowing down, and to raise diagnostic confidence without demanding heroics from technologists already stretched thin.

Use cases, impact, and caveats

In day‑to‑day operations, these capabilities translated into distinct wins. Automated tube and detector movements, plus live camera guidance, shortened room turnover and tempered the variability that sneaks into high‑throughput schedules. At the bedside, live positioning cues and auto SID sensing helped technologists capture diagnostic views on the first try, even when patient repositioning was unwise. In the OR, sustained, low‑dose fluoroscopy with crisp visualization supported complex vascular and orthopedic work, where every second and every milligray is negotiated. MRI planning and reconstruction gains closed the loop by taming setup time and reconciling speed with fidelity, which raised scanner utilization while protecting consistency across sites.

Still, claims remained directional rather than comparative. Actual gains depended on training, integration with RIS/PACS, and local case mix. Sites that mapped automation to standard protocols, audited dose by indication, and enabled coaching features by default saw the clearest benefits. The portfolio therefore created a pragmatic next step: inventory protocols against the new capabilities, align staff education with device guidance, and schedule shadow sessions that translate features into habits. By treating automation as a catalyst for culture—consistent planning, disciplined geometry, and first‑time‑right exposures—departments were poised to convert feature sheets into measurable throughput, steadier dose, and more uniform diagnostic quality across rooms, carts, and suites.